Volkswagen, the company that brought us Dieselgate, wants us to forget its last eco-disaster by promising to bring affordable electric cars to the masses starting in 2020. Those cars will ride on an all-new electric platform called MEB. The automaker calls it “one of the most important projects in the history of Volkswagen,” and says MEB will underpin more than 1 million EVs per year starting in 2025. Last fall, I had a chance to look at the new architecture and speak with some engineers. Here’s what I learned.

(Full Disclosure: VW wanted to show me its new MEB platform, so the company flew me to Dresden, fed me potato soup and schnitzel, and put a nice roof over my head.)

Volkswagen brought journalists to its glass factory in Dresden for the world premier of the automaker’s Modular Electric Drive Matrix, or MEB, platform, which the company promises will be the “economic and technological backbone” behind its goal to bring EVs from niche into the mainstream. The result of clever platform sharing, VW told journalists, will be electric cars with pricing similar to that of a “comparable diesel car.” A more recent story by Reuters stated that VW could sell an entry level MEB vehicle for as little as $23,000.

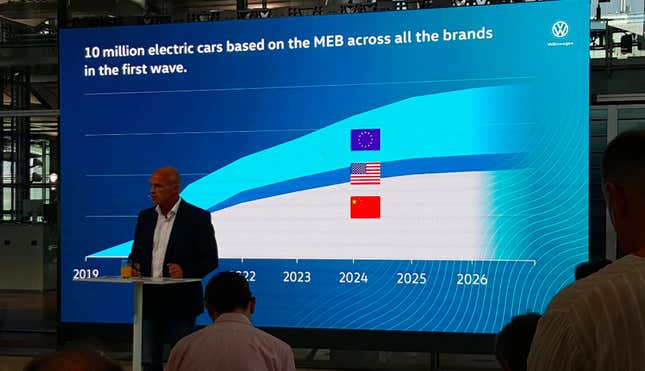

VW plans to build 150,000 electric cars in 2020, (100,000 of which will be the I.D. compact car and I.D. SUV, which are both expected to premiere in 2020), offer 27 all-new EV models across four brands by 2022, and offer an electric version of every single one of its 300+ models by 2030. In total, the company expects to build at least 10 million EVs based on this new MEB platform, and Reuters reported last month that this could go up to 15 million.

But we’ve been hearing a lot of companies announcing lofty electrification plans like these, so what makes VW different? Well, they’ve at least got hardware to back up the talk. Here’s a look at what might be the platform that actually brings electric cars to the masses.

The MEB Platform

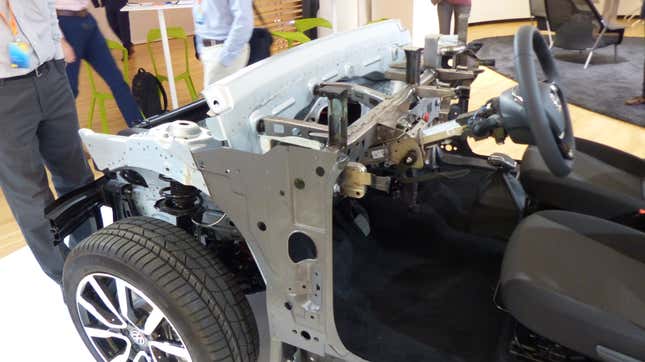

VW started designing the MEB platform—the company’s very first high volume EV architecture—about three years ago. Like Tesla vehicles, it comes in either rear-wheel drive or all-wheel drive configurations, and is built around a flat, rectangular battery pack that’s bolted beneath the vehicle’s floor.

This all makes it closer to a Tesla than to a Fiat 500e or a number of other EVs from mainstream manufacturers that use normal car platforms modified to be electric. Those cars tend to have batteries crammed under seats and other drive components sandwiched where an internal combustion engine would be. That and they’re usually front-wheel drive only.

The VW ID layout—with its short hood and long wheelbase, lack of driveshaft or exhaust tunnel, and small overhangs—promises a low center of gravity, high cabin and trunk volume, and also a higher seating position compared to an internal combustion engine vehicle in the same class.

Speaking of that higher seating position, Volkswagen says the ID’s giant 18- to 21-inch wheels were sized, in part, to help provide the thick battery pack with the additional ground clearance it needs. By contrast, today’s Golf can be had with 15-inchers.

That low-mounted battery, which will initially come in roughly 50 kWh and 80 kWh sizes (more to come in the future, VW says), is expected to offer between 205 and 342 miles of range on Europe’s new WLTP cycle, or around 175 to 300 miles on the EPA cycle.

One Architecture for Many Vehicles

Early this decade, Volkswagen introduced the Modular Transverse Matrix, or MQB, an extremely flexible car platform that allowed the company to share as many components and assembly processes across as many vehicles as possible. It can span cars like the small VW Golf up to the giant seven-passenger VW Atlas as efficiently and inexpensively as possible. In total, MQB currently represents 80 percent of VW Group’s sales volume, with about 55 million having been produced thus far.

MEB is essentially this same platform strategy but applied to electric cars. It is supposedly capable of underpinning everything from the aforementioned I.D. compact car (which VW also refers to as the “Neo”) and I.D. Crozz SUV, to a sedan based on the I.D. Vizzion concept, to a modern interpretation of the VW Microbus based on the I.D. Buzz concept. Production versions of the latter two are scheduled for launch in 2022.

Tino Fuhrmann, the head of the MEB project, actually says MEB offers “less variance than the MQB platform,” making it an economical way to build different kinds of electric cars with as little complexity as possible.

The platform will be primarily built of conventional materials like steel, though there were a few aluminum components on the chassis shown in Dresden, including the steering knuckles and the battery housing. Different vehicle segments are expected to get different aluminum content, with the I.D. Vizzion sedan, for example, getting more than the cheaper, compact Neo.

This aligns with Tesla’s strategy of using mostly steel on the cheaper Model 3 rather than an aluminum-intensive body design like those of the Model S and Model X. By contrast, the probably over-ambitious BMW i3 had a body structure made entirely of carbon fiber, but that, according to Car and Driver, may be a thing of the past thanks to battery advancements, quoting head of BMW’s i Division Robert Irlinger as saying:

“At the time of the BMW i3, the capacity of batteries was still quite low, and so we tried to get every kilogram out of the car to reduce the amount of energy we needed [to power it]...But, with the improving energy capacity of batteries, you don’t need to look for the last 500 grams. Therefore, we look for the right balance of properties. Carbon fiber is still an extremely important material when it comes to passenger safety, for example, but you only use it in certain areas.”

So the MEB’s steel design makes sense for an entry-level EV. Fuhrmann described how the platform could be elongated and widened for different applications. Firstly, the wheelbase can simply be stretched:

Second, the track width can be increased by making changes to the suspension, including to the lower control arms:

And finally, Fuhrmann said additional length could be added between the pedals and the front axle for premium vehicles like the I.D. Vizzion concept, likely along the crease in the cowl shown below:

The Powertrain

Volkswagen hasn’t revealed exactly how much horsepower its MEB vehicles will have, but the company mentions in its press literature that the rear-wheel drive I.D. concept car shown at the Paris Motor Show in 2016 had an output of 125 kW, or about 168 horsepower, and after speaking with VW, Autoweek wrote that the front motor on all-wheel drive MEB models could have median outputs of between 55 and 65 horsepower.

The I.D. Vizzion and I.D. Buzz cargo concepts were both powered by a 201 horsepower motor in the rear, and the former also had a 100 horsepower unit up front according to VW. So 150 to 200 horses in the back and 50 to 100 horses up front seem like a reasonable guesses.

To put that in some more context, the Chevrolet Bolt, by comparison, offers a single motor up front producing 200 horsepower, while the Nissan Leaf puts out 147. The Tesla Model 3 Long Range’s rear motor produces 258 horsepower, and the all-wheel drive Dual Motor Performance models make up to 450 ponies combined, according to Motor Trend. (It’s worth noting that the combined figure on the all-wheel drive model is not just the sum of the two motor outputs).

I also don’t know exactly which type of motor will be used up front or what, other than output, will make it different than the one in the rear, but I do know that the rear unit will be a Permanent Synchronous Motor or “PSM.” This motor and whatever’s used up front, VW says, will be the only two motors offered across the entire MEB line of at least 10 million vehicles in the automaker’s “first run.”

Yes, according to Fuhrmann, there will only be “two available motors for the entire platform.”

Despite this, motor output and acceleration, Fuhrman said, can be varied based on model via software changes and different ratios in the gearboxes, of which there will be two available across the entire MEB line for each the front and rear motor.

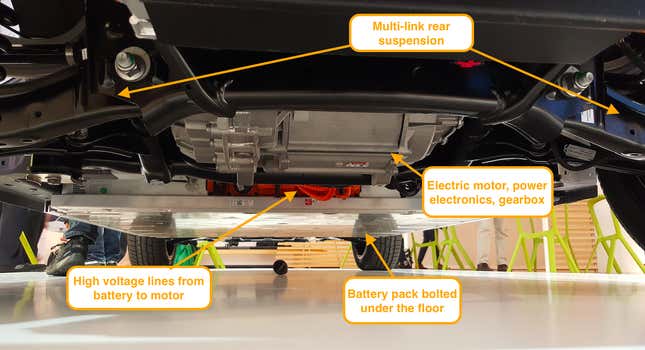

Those gearboxes will be housed in single units with the motors, as well as with the power electronics that convert DC current from the battery to AC current for the motors.

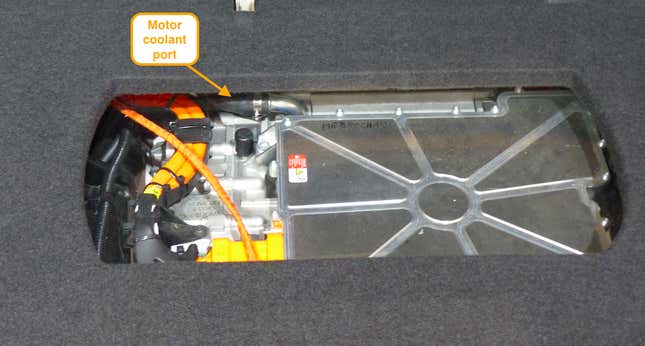

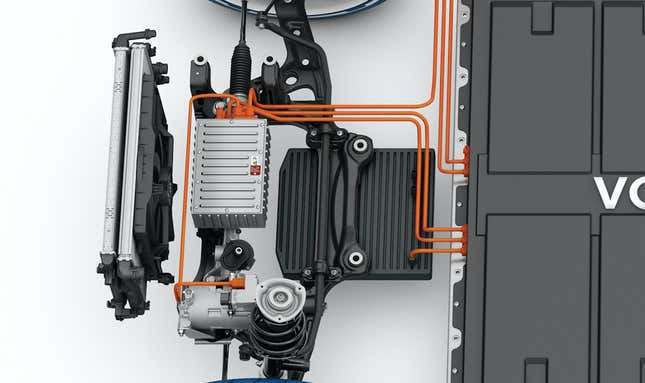

The image above shows that motor/gearbox/power electronics unit, as well as the flat battery pack bolted to the floor from below, the high voltage lines from the battery to the motor, and the multilink rear suspension. (There’s a MacPherson strut setup in the front.)

The motor unit and battery pack are both liquid cooled, with the latter in a low temperature loop that includes a chiller (a refrigerant-to-coolant heat exchanger that allows for additional cooling beyond what a passive water-to-air radiator at the front of a typical automobile could offer) and the former in a high-temp loop.

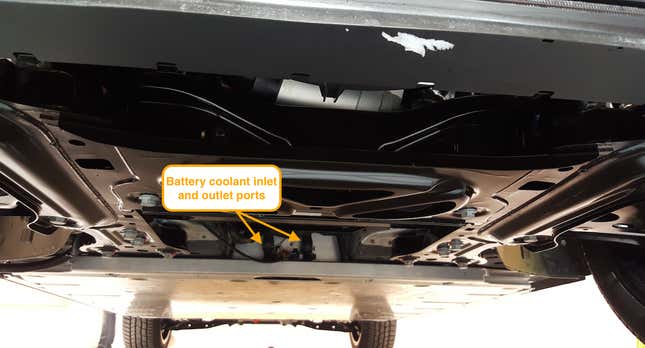

You can see the coolant hoses going to the motor in the photo above the previous one, and here’s a look at where the coolant lines enter and exit the front side of the battery pack:

Auxiliary Components

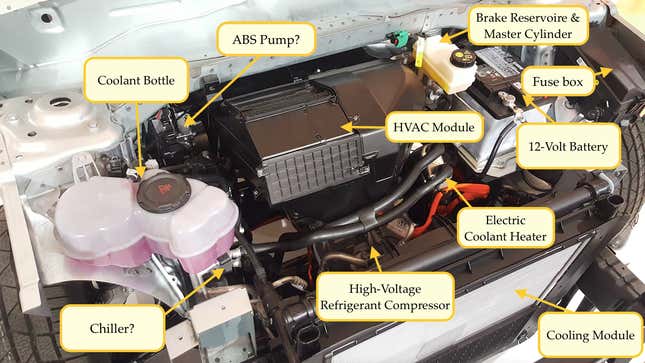

Under the hood, there’s still a 12-volt battery to power the vehicle’s onboard electronics and a large black HVAC module that’s normally found behind the dash in a typical non-electric vehicle’s interior. Down below towards the bottom of the car, there’s a high voltage refrigerant compressor, and to its right is a resistance heater for warming up the coolant that flows into the battery.

I’ve labeled some of the components above; if you’d like a short tour of the underhood area, let VW MEB Product Manager David Holbein show you in this Autogefühl YouTube clip:

I didn’t have a chance to take a close look at the model’s cooling module (the stack of heat exchangers at the front of the car), but VW did say that there’s only a single radiator at the nose. This makes me think that the design is much like the Tesla Model 3's, which has one air-to-water radiator up front, along with an air-to-refrigerant condenser for the battery chiller (you can see the Tesla’s full schematic here).

And indeed, in the press image below and the photo above, I do see two heat exchangers, which back up that hypothesis, though I will say that, when I spoke with a VW engineer at a round table at the LA Auto Show in November, he seemed strangely hesitant to discuss the particulars about the cooling module.

And in an email with VW’s PR rep, I was told that the company wasn’t ready to discuss it further, making me wonder if VW’s got some kind of clever battery and motor cooling design brewing.

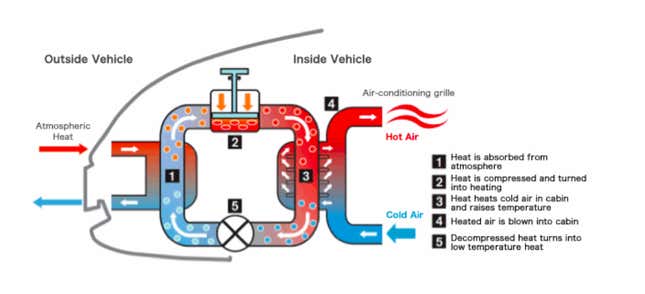

Speaking of the cooling system, MEB-platform cars will have an optional heat pump, which is sort of like an air conditioning system in reverse, using heat from the powertrain and the outside environment to warm the cabin rather than relying solely on a battery powered electric heater. VW expects to yield an improvement of over 10 percent in overall range in the winter.

The MEB’s system is likely similar in concept to what’s offered in the Nissan Leaf (whose schematic is shown above) and the current Volkswagen e-Golf, whose heat pump VW explained in a 2013 press release, saying:

...offered as an add-on module for the electric heating (high-voltage heater) and the electric air conditioning compressor, the heat pump utilises both the heat from the ambient air and the heat given off by the drive system components. In this way the high-voltage heater’s consumption of electric power is significantly reduced. Through use of the heat pump the e-Golf’s range increases in winter by up to 20 per cent.

If I had to guess, that heat pump will be packaged under hood somewhere, as it seems like VW has focused on maximizing interior space over allowing for a “frunk” for cargo items.

That’s right, don’t expect a frunk on MEB vehicles, which is odd to not see on a car made off of a dedicated EV platform, one that wasn’t designed to have an engine up there. Sad, I know, because frunks are awesome.

On the topic of under-hood packaging, the bare MEB platform shown in Dresden was rear-wheel drive, and there didn’t appear to be much room up front for a motor. Fuhrmann told journalists that the HVAC box and the DC-DC converter—which I think sits below the HVAC box shown below and above—would have to move to accommodate a front motor, though its not clear where they’d be relocated.

These are just a few bits of hardware I noticed while sliding underneath the MEB and gazing under its hood. I hope to take a closer look soon.

Why Rear-Wheel Drive?

So you might be wondering: Why rear-wheel drive instead of front-drive? After all, VW’s had a pretty scant history of front-engine, rear-drive cars—it went pretty quickly from rear-engined, air-cooled cars to front-drive water-cooled ones in the 1970s and onward, adding AWD as needed.

When asked that question, Fuhrmann said the placement of the majority of the vehicle’s weight—between the wheels (because of the battery) instead of above the front wheels as seen on most front-drive cars of today—meant the rear wheels made the most sense from a traction standpoint. On top of that, he said, rear drive offered better vehicle agility.

“The rear-wheel drive is absolutely the right one for the electric drive,” he told journalists. He seemed convinced.

This is good news, because while car enthusiasts might decry the electric car revolution for the further death of manual transmissions and also the death of roaring engine sounds, at least some future economy cars will send power to the right set of wheels.

It’s fair to note that while front-wheel drive has been the standard for front-engine cars for decades, rear-wheel drive in economy cars was never unusual on cars that didn’t have a heavy internal combustion engine up front. Europe in particularly used to be churning out RWD economy cars from the 1930s through the early-to-mid 1970s, before everyone went universally front-engine on applications like this one.

The Interior

In the photo above, Fuhrmann is showing journalists the 30 liters of volume between the cowl and the instrument panel beam on the I.D.. Created by moving the HVAC forward into the front of the car, the space provides more area for what VW says will be a massive augmented reality head-up display, which the brand has been touting as a major feature in all of its I.D. concept vehicles. This space, Fuhrmann told journalists, could only be possible by reinventing a completely new platform.

Inside, occupants do sit fairly high up thanks to that tall battery pack, and there is a slight “tunnel” in the center, though it’s small and exists for the coolant lines that go from the cooling module up front to the battery in the middle and the motor in the rear. In addition, it’s meant to clear high voltage cables that go from the rear of the battery pack to components underhood like the high voltage compressor, high voltage heater, and DC-DC converter.

The Battery

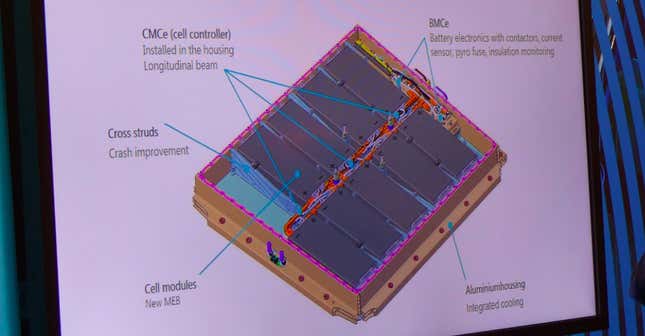

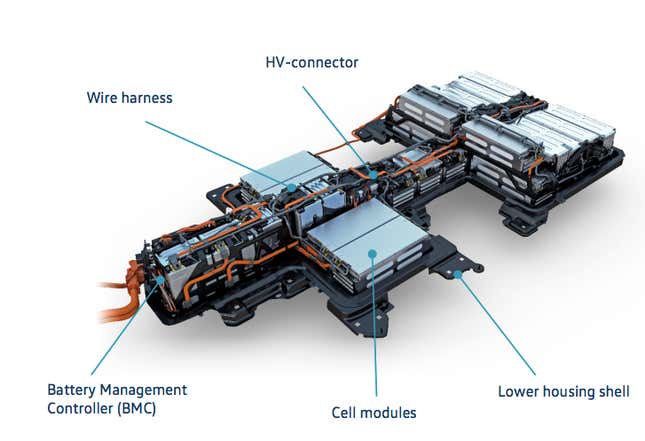

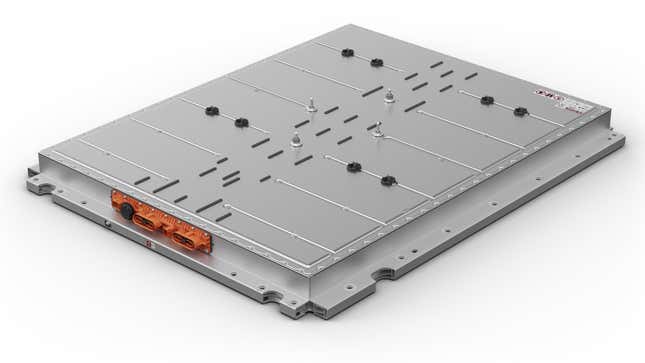

Volkswagen calls its lithium-ion battery pack a “chocolate bar” design comprised of a number rectangle-shaped cell modules, which are housed in an aluminum case that has a heat exchanger integrated into its bottom.

As shown in the image above and below, the rear of the housing includes a Battery Management Controller, and while I’m not sure exactly what it does on the MEB platform, on the e-Golf, this part was in charge of functions including “regular diagnosis and monitoring to helping regulate temperatures in the battery junction controller,” VW writes in an old press release.

Between the two rows of modules sit cell controllers, which are used for monitoring cell current, voltage, temperatures (VW told journalists that temperature is technically monitored on the module level) and also for cell balancing to ensure longevity and optimal performance.

Volkswagen plans to use two different kinds of cells in the modules within the MEB battery packs: prismatic and pouch cells (you can see them both below), since round cells wouldn’t package as densely.

LG will supply the pouch cells and Samsung will provide the prismatic cells. VW told me that any vehicle could have one or both of these cell types in its modules. Using these two battery types was done on purpose, VW says, to afford a “high degree of flexibility in the cooperation with cell suppliers.”

Also using pouch cells are the Nissan Leaf, the Chevy Bolt, and the Jaguar I-Pace electric SUV, with the first having Nissan’s own cells, and the latter two—like VW—getting theirs from LG.

According to Korea Times, Jaguar Land Rover has been talking with Samsung about using 21700 cylindrical cells, which Tesla has been manufacturing with Panasonic for the Model 3, touting the cell’s low cost and high energy density.

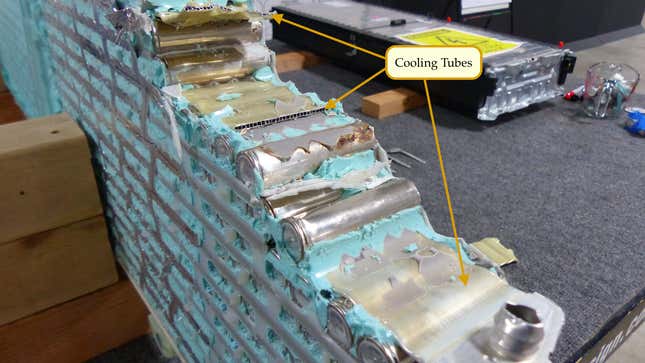

You’ll notice in the picture above a zigzag-shaped gray substance. That’s what’s found below each module, and it’s called thermoconductive gap filler, helping ensure that heat from the battery cells gets transferred to the heat exchanger integrated into the case below.

Speaking of that heat exchanger, both the inlet and outlet ports are in the front side of the case, as shown before in the underbody photo, and more clearly below:

By contrast, Tesla actually winds coolant tubes between individual cells, rather than below modules. Here’s a look at the Model 3's battery cooling setup:

Also shown in the cutout in the corner of the VW’s battery pack above is what appears to be a protective (possibly steel?) plate, which I assume is the “solid collision protection” that VW mentions in its press release sits below the aluminum battery case, and likely acts to avoid battery cell puncture. The Tesla Model 3 and the Chevy Bolt do things a little differently, with a manufacturing expert at auto benchmarking firm Munro & Associates telling me that the two vehicles have battery cases whose outsides are made largely of stamped steel, with no obvious separate shield. On the other side of the MEB’s battery pack is a thin cover that can be unbolted for maintenance.

In the diagram a few pictures up and in the picture above the last one, you’ll notice aluminum “cross struts” between the modules. Those are there for crash protection, increasing the stiffness of the battery pack, which is important, since it is a structural part that adds to the vehicle’s overall rigidity.

VW contrasts this flat battery pack setup with that of the e-Golf, an internal combustion vehicle that was modified to fit batteries, and not a purpose-built EV. Its odd shaped battery, VW told us, isn’t cost or weight effective, requiring long connectors and strange mounts. The MEB battery, on the other hand, is apparently easier to scale up, easier to cool, easier to install, and—of course—it lowers the center of gravity and can yield more interior space.

MEB’s battery voltage will depend on the number of cells and cell types, VW says, but at the beginning of production, nominal voltage will range between 300 and 400 volts. Battery pack capacity will be either 48, 62, or roughly 82 kWh, with the 48 kWh and 62 kWh sharing the same pack (the 48 kWh simply has two fewer cell modules), and the 82 kWh pack having a different, larger housing. The smallest battery promises 175 miles on the EPA cycle, the biggest will get a projected 300 mile range, and the 52 kWh pack will be somewhere in between.

By comparison, the Tesla Model 3's long range and mid range battery packs offer an EPA-estimated 310 and 264 miles of range, respectively (Electrek says those respective packs have capacities of 74kWh and 62 kWh), and there’s standard battery with an expected 220 miles of range slated for later. Also, the Chevrolet Bolt’s 60 kWh battery pack is good for 238 miles, and the Nissan Leaf offers a 40kWh pack with 151 miles of range; a 60kWh Leaf with a projected 225 mile range is expected to debut soon coming soon.

So the VW’s 175 mi to 300 mi estimate for the 48 kWh to 82 kWh packs seem competitive—perhaps a bit short for the 82 kWh pack, but again, we’ll have to see when the EPA figures come out how close those estimates are to reality.

VW says even the smallest of the MEB cars will be able to house the largest battery pack, and all cars have packaging space reserved for inductive charging.

On the topic of charging, VW mentioned a maximum charging rate of 125kW, which can apparently charge a battery pack to 80 percent in 30 minutes. Green Car Reports and other car news outlets state that, initially, that 125kW charging capability will be limited to the largest 82 kWh battery pack, with the smaller two limited to 100 kW.

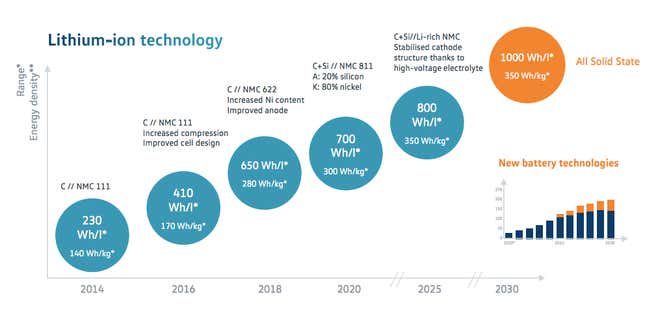

VW’s cells will start as NMC—Nickel Manganese Cobalt —622s (cathode chemistry that is fairly standard in the auto industry today, but not used by Tesla), as reported by German newspaper Handelsblatt. But, as shown in VW’s image above, by 2020, the company thinks the higher energy density, lower-cost NMC 811 cells will be ready—cells that are being touted by some as the future of electric car batteries, and key enablers to bringing EVs mainstream.

How long it will take for VW to transition to these cells is unclear. Also, as shown in the plot, solid state batteries are still on the horizon. VW did mention its partnership with California-based tech company Quantumscape, and said a solid-state battery trial project is scheduled between 2023 and 2025.

How VW Plans to Bring MEBs to the Masses

Economies of Scale

In his speech, Thomas Ulbricht said there are three “pillars” that VW is basing its electric vehicle strategy on: the MEB platform itself, economies of scale, and infrastructure. We’ve already looked at the platform, and for economies of scale, Ulbricht has big plans.

VW says it will build the electric cars in 16 “e-locations” around the world by late 2022, including some in Europe and one plant in the U.S. VW isn’t sure exactly where, but calls Chattanooga a “natural fit.” Most of the plants, though, will be in China, where about 50 percent of 2025's 1 million annual EVs will be sold, with Europe representing about 30 to 40 percent, and the U.S. representing around 10 to 20 percent.

Of the roughly $39 billion VW says it will invest in future tech by 2022, around $1.4 billion will go to the Zwickau plant in Germany, where the first ever MEB model—the Volkswagen I.D. four-door compact car—will go into production in late 2019 as the facility begins its transition from internal combustion engine vehicles to fully electric and fully MEB by the end of 2020. Annual volume of MEB-based electric cars out of Zwickau is expected be a staggering 330,000 vehicles per year. (For some context: In 2015, BMW’s South Carolina plant—which builds nearly all the SUVs that BMW sells globally—made about 400,000 cars. In other words, VW’s output of EVs is going to be huge, a gamble as big as the investment itself.)

There are, of course, challenges with reliably obtaining all those batteries, which is why VW is working with not just LG and Samsung, but also battery companies SK Innovations and CATL.

To ensure a reliable supply chain when it comes to batteries, VW says it actually meets with LG’s board in Poland every second week to help get the company ready for cars. Thomas Ulbrich outlined the supply-chain related risks, with Automotive News Europe quoting him as saying:

“There are risks in third- and fourth-tier areas, especially in these new technologies. This is the reason why we created this task force with LG Chem,” Thomas Ulbrich, the VW brand’s management board member responsible for electric mobility, told reporters in Dresden, Germany.

[...]

“The battery cell availability is for us the base really to produce the cars,” Ulbrich said, “but we are taking care of it.”

As for other components, Ulbrich said VW in Europe would use primarily its existing supply chain used to build millions of VW Group products in Europe. He also said, when asked about building in the U.S. rather than Mexico, that VW feels responsible for “built in America,” mentioning that the U.S. has a stronger supply chain than its southern neighbor.

Infrastructure

But we all know that one of the major issues that could bring VW’s lofty electrification plans to a halt is the lack of a charging network.

Among things the company mentioned on this topic was the debut of a new 11 kW “wall box” at-home charger that VW says will be available in all markets when the Neo launches, and will start at 300 euros in Europe. This is not dissimilar to the Wall Connector that Tesla sells for $500.

In addition, VW dealerships will become EV charging locations. “Our dealer will become a publicly available charging network,” VW’s head of e-mobility services Martin Römheld told journalists, going on to say that all 4,000 VW brand dealership and service centers in Europe must have two 11kW AC chargers and one 20kW DC charger by the time the ID “Neo” launches in 2020, and that every new dealer from here on must have those chargers as part of their plans. This is similar to what Nissan did for Leaf owners, with varying degrees of success.

Volkswagen also highlighted the fact that it—along with Ford, Daimler, and BMW—cofounded Ionity, a charging network in Europe that plans to build 400 stations by 2020 (47 are currently operational). And the Wolfsburg-based carmaker mentioned Electrify America—a company created as a part of the automaker’s Dieselgate settlement with the U.S. government—as a key to helping solve the infrastructure issue.

These are obviously tiny steps considering the vast expense associated with building EV infrastructure, but they’re at least something.

Is This The Platform That Brings EVs to the Masses?

The electric car revolution has already begun thanks in large part to government regulations and incentives in China, Europe, and even the U.S., and also thanks to solid EV offerings from Nissan, Chevrolet, and Tesla.

VW has clearly taken quite a bit out of the latter’s book with the flat skateboard-like battery, rear-wheel drive setup, and the mostly steel design. But while Tesla is relatively new at large scale manufacturing and learning as it goes, VW is a manufacturing powerhouse with clever platform-sharing skills, enormous volumes, and a diverse supply chain, so it will be interesting to see just how affordable the company can make EVs.

And, even more so, whether people will buy them, and whether infrastructure can keep up.

Correction (Jan. 8, 2019 4:10 P.M. ET): This post has been corrected to indicate that Tesla’s battery pack rated at 264 miles of range is called the “mid range” battery, and not the “short range” battery.

Correction (June. 14, 2019 9:15 A.M. ET): A former-latter mixup has been corrected to make it clear that the battery is in the chiller cooling circuit, and the motor is in the high temperature circuit, not vice versa.